Inside the coffee roasting machine – What happens to the beans in a coffee roaster?

This article has been reviewed for accuracy by Dr. Richard Muhlack, Senior Lecturer at the University of Adelaide’s School of Agriculture, Food, and Wine.

Introduction

Roasting coffee is a process that billions of people are aware of, but very few people have a detailed understanding of. Coffee is one of the world’s most popular drinks, with over 400 billion cups consumed every year[1], meaning that every day, coffee roasting is happening all across the world on a massive scale. And yet, unless you’re a professional coffee roaster (or one of the steadily growing number of home coffee roasters), you’re unlikely to know much about what happens to a bean while it’s in the coffee roasting machine.

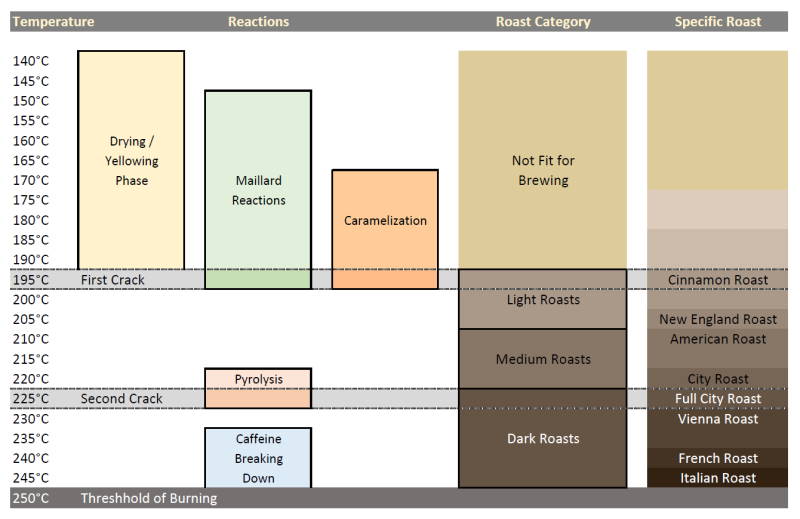

In this article, we’ll look at the timeline of what occurs to green coffee beans as they roast, how the native flavour of the beans and the flavour imbued by the roasting process interact, and what chemical processes the beans go through as they remain in the roaster. We’ll also examine exactly what types of coffee roast (such as French Roast, City Roast, etc.) correspond to which phases of the roasting process.

Green beans – how does the coffee start?

The raw materials needed for coffee roasting are green coffee beans – the seeds of the coffee plant, extracted from ripe coffee cherries by one of the various coffee bean harvesting processes (the most common being the ancient and simple “Dry” process, or the more modern “Wet” process). These are supplied as raw beans (although they’re technically seeds) still coated with a protective layer of plant matter known as the “silverskin”. Green beans are regarded as the preferred state for storing coffee long term as they have a relatively low moisture content (having been pre-dried to around 10–12% w/w) and are ready for roasting, but their shelf life is far longer than roasted beans – green beans remain relatively fresh for 12-18 months in a climate-controlled environment. This is as opposed to roasted beans which have an optimal life of a week or two, and ground coffee, which is ideally consumed immediately after grinding (preferably within 15 minutes).

Of course, the degradation of roast coffee beans and ground coffee can be delayed with proper storage in a cool, dry, dark, low-oxygen environment. This is why ground coffee sold in supermarkets retains much of its freshness until opened, as the plasticised foil bags prevent the coffee from being exposed to oxygen, moisture, or light.

Green beans are small and extremely dense – to the point where many coffee grinders would struggle to grind them successfully – not to mention the fact that green beans would have an unpleasantly sour vegetal taste if you tried to brew with them.

Blends vs single origin coffee

Not all green coffee beans are the same, and beans can come from a vast array of different sources – coffee is grown in many locations around the globe. Although the chemical processes that occur within the beans during roasting aren’t affected by their point of origin, the reverse is true – the individual flavour profile of the beans can be affected (or even overpowered) by the roasting process. This means the source of the green beans should factor into how beans are roasted.

In particular, while many commercially available coffees are a blend of many different types of coffee beans (in order to achieve reasonably consistent coffee flavours for a specific brand), in recent years, there has been a significant upsurge of “single origin” coffees – originating from a specific region, farming co-operative, or even an individual coffee farm. This is analogous to wine growing – with large brands blending stock for a consistent flavour and small wineries producing a less consistent but generally higher quality product.

These single origin coffees are significant in two ways. First, their quality tends to be quite high (for the speciality coffee market). Secondly, they tend to have a distinct flavour profile from other coffee types, which speciality coffee roasters generally look to feature in their product. This means certain roast types are less suitable for single origin coffees. We will examine the significance of this to the roasting process below.

The roasting process

There are thousands of chemical reactions that take place within a coffee bean while it’s roasting. While it’s not realistic to describe each of these in a single article, there are a number of key processes and reactions which occur during roasting that are key to the developing coffee flavours, and serve as milestones that a professional coffee roaster can use to track the process.

In reality, the roasting process is not always the same – professional coffee roasters tend to have specific “roast profiles” – a form of specialised recipe which dictates the temperature used at different phases of the roast. Roasters might use a variety of roast profiles depending on the beans, the roaster, or various other factors. But regardless of the specific roast profile, the principle is the same – the beans are slowly heated up to a desired temperature, going through a number of specific changes[2] as they reach specific temperatures.

It is common for coffee roasters to pay careful attention to colour as the beans roast, as this often indicates the progress of the beans through the roasting process. Unfortunately, it is not always a reliable indicator, as several factors affect the colour of the beans – with age being one of the primary ones (coffee beans darken over time). As such, roasters normally rely on a combination of temperature, smell, colour and sound cues to track the progress of the beans through the roasting process.

Initial Heating

Before the beans are added, the roaster must first be preheated to a specific “charge temperature”. This temperature will generally be part of the roast profile and varies with factors such as the type of roaster (air roaster vs drum roaster), the intended length of roast, and the type of bean used. If the charge temperature is too low, it will slow down the roast process, meaning the beans end up “baking”, yielding a flat or “hollow” coffee flavour[3]. If the charge temperature is too high, the outer layer of the beans may burn before the inner layer is cooked – a process known as “scorching”.

Once the coffee roasting drum has been brought up to charge temperature, the green coffee beans are added, and the roasting process begins. As they warm from room temperature up to around 150°C, the beans go through what’s called the drying or yellowing phase – so called because the beans change from pale green to pale yellow in colour. During this phase, the beans begin to gradually lose moisture, beginning to drop down from their initial level of 10-12% moisture (once fully roasted this level will drop to around 2.5% w/w)[2]. They will also begin to swell as the bean’s moisture evaporates to steam, forcing it to expand. The odour given off by the roasting beans is often described as being like toast or popcorn.

During this period, the process is endothermic – meaning it absorbs heat from the roaster, which then drives the chemical reactions.

Maillard Reactions

Once the beans reach around 150 – 160°C, the beans will exhibit the Maillard reaction – this is a very common chemical reaction in cooking (technically a non-enzymatic browning) which is responsible for the brown colours in baked and fried foods and cooked meat, and produces many of the more desirable flavours in cooked food[4]. In roasting coffee, hundreds of flavour compounds are developed within the bean in the space of a few minutes, all interacting to create distinctive coffee flavours.

Caramelisation

Once the coffee beans reach around 190°C, the beans begin to caramelise. The aroma of the beans starts to shift from being bread-like to taking on a sweeter quality. The sweet flavours within the bean go from being like refined sugar to having a more satisfying honey-like quality[5]. Acids are also released at this phase, giving lighter roasts more of a sharp flavour. The beans keep expanding as the moisture inside continues to evaporate to steam.

First Crack

As the internal temperature of the beans reaches around 205°C, the steam pressure will have forced them to expand right to breaking point. At the same time, the bean’s outer layer will become increasingly brittle during the roasting process (unroasted green beans are tough and leathery in texture). Eventually, the pressure of the steam inside will rupture the bean in a process referred to by coffee roasters as “first crack”.

First crack is an audible cracking sound made by the roasting coffee beans as each bean cracks open, allowing the steam inside to leak out. The sound is sometimes described as similar to popcorn popping[6].

At this point, the roasting process becomes briefly exothermic – meaning the beans generate their own heat as they vent steam rather than simply absorbing heat from the roaster. This burst of additional heat can affect the roasting process, so some roast profiles will actually adjust the temperatures to make allowance for this.

By this point, the beans will also have shed their outer layer of silverskin – which will have dried out and flaked off as the bean expanded. This excess silverskin – a light and flakey residue known as chaff – is one of the main waste products of the roasting process, and part of the regular routine of professional coffee roasters is cleaning it out of the roaster and disposing of it.

Once first crack has started, the beans are reaching the level where they could potentially be removed from the roaster and used for coffee brewing. Coffee roasted right to the point of first crack and no further is a very light brown (hence the name) and tends to have pronounced, sharp acidity – often tasting sour – with prominent toasted grain flavours and underdeveloped sweetness. This is called “Cinnamon Roast” and is generally the lightest type of roast that coffee roasters consider drinkable (“white coffee” {https://www.homegrounds.co/what-is-white-coffee/} is a method that produces even lighter beans, but this is achieved through baking, not roasting).

Once first crack has concluded (with each of the beans having cracked and released their steam), the roasting process continues, with the beans growing slowly darker and darker. At this point, bean roasters begin to use other terms for the level of roast. Once the beans have darkened beyond the level of a Cinnamon roast, this is generally referred to as a “New England Roast”. Still considered a light roast (some people use the two terms interchangeably), New England roast is popular with speciality roasters as it highlights the distinct flavours found in single origin coffee. Such coffees often feature complex acidity.

Left to roast longer, the beans will then progress to a middle roast. The bean colour is becoming progressively browner now, taking on a rich chocolate colour – although the surface is still matte and unreflective. At this point, the roasting process has begun to make the acidity less pronounced, although the origin flavours are still preserved and relatively prominent. The medium roasts include American roast and City roast (generally in that order, although again, the terms are sometimes used interchangeably).

Medium roasts are often regarded as a good middle ground for coffee, as the roasting process has now muted much of the acidity, but the origin flavours are still preserved. The beans are also exhibiting more “Roast character” – taking on flavours from the roasting process itself. Medium roasts are the most popular type of roast in the United States[7] (hence the name “American roast”).

Pyrolysis (220°C)

Late in the medium roast stage, as the temperature in the bean reaches around 220°C, the beans undergo a chemical reaction known as pyrolysis, during which carbon dioxide (and other volatile compounds) are released from the bean’s structure, and various chemical changes occur that affect the flavour (more specifically, larger chemical molecules are broken down into smaller ones[8] by the heat, releasing CO2 in the process). This modulates the acid flavours and produces a more rounded and integrated flavour within the bean. The beans lose additional weight at this point (around 13%), as the carbon dioxide is slowly expelled.

Second Crack (230°C)

Once the beans reach around 230°C, they experience what coffee roasters refer to as “second crack”. Just as the build-up of steam pressure from caramelisation eventually caused the structure of the bean to break open and vent the steam, the now brittle beans crack open again to allow the built-up carbon dioxide from pyrolysis to escape. Like first crack, this involves an audible popcorn-like cracking sound which coffee roasters listen for as an indicator of the current roasting stage of the beans.

As with first crack, during second crack the process becomes exothermic for a short period – the beans generating their own heat in addition to the heat of the roaster.

Once the second crack has occurred, the beans are generally regarded as dark roast. This is visibly characterised by dark chocolate colours ranging from dark brown to almost black. The beans also become shiny, as oil from inside of the beans now leaches to the surface to coat the beans and give them a glossy appearance.

Once beans have reached the dark roast stage, the flavour has become strong and full-bodied, but the dominant flavours are generally from the roasting process – at this point, the roast character has normally overpowered the distinctive flavour profiles of single origin and speciality coffee. As such, blended coffee beans are generally more suited to dark roasts. The flavour is generally more bittersweet, with caramel overtones and very little acidity.

Interestingly enough, dark roasts tend to have less caffeine than earlier roasts, rather than more. The reason for this is that caffeine begins to degrade at temperatures over 235°C (it has a melting point of 238°C[9]). As such, once the beans have heated past second crack and are reaching the dark roast stage, the caffeine in the bean is starting to break down.

Types of dark roast include Full City roast (generally roasted to around 225°C, just at the beginning of second crack), Vienna roast, French roast, Italian roast, and Spanish Roast. The darkest roasts (where the beans have been heated to around 240 – 250°C) have characteristically strong, bitter coffee flavours, which don’t appeal to every palate – but which, as the names suggest, are particularly popular in Europe. These often have a smoky taste, as the beans are close to burning at this point.

If taken beyond the dark roast stage (over 250°C), the oils and sugars in the bean start to burn, and the beans are no longer usable[7].

Roasting processes at different internal bean temperatures

Once the coffee has been heated to the desired roast level, they’re then removed from the roaster and cooled to halt the roasting process (otherwise, the heat trapped within the beans could continue the roasting process internally). There are two primary methods of cooling coffee beans after roasting – air and water[10].

With air cooling, ambient (room temperature) air is passed through the beans, cooling them down by convection (the same principle as blowing on hot soup to cool it). This generally takes place in a separate cooling unit, although this can sometimes occur in the roasting drum. The advantage of air cooling is that it adds no moisture to the beans, which lengthens their shelf life (they take longer to go stale). This reduces overall bean wastage.

By contrast, water quenching involves spraying the beans with a small amount of water to allow cooling by evaporation. Once again, this can happen in a separate cooling unit or in the roasting drum itself, depending on the design of the drum. The moisture introduced to the beans swiftly cools the beans, and helps them regain some of the aromas lost during the roasting process.

Degassing

As enticing as the smell of freshly roasted coffee might be, it’s not ideal to grind and brew coffee immediately after roasting. The reason for this is that regardless of the roast level, the beans will have residual carbon dioxide remaining in their structure. This excess CO2 can affect the taste of the brewed coffee, and impede the water from extracting coffee flavour by preventing it from soaking into the cells of the coffee granule.

The solution to this is allowing the coffee beans to degas. Degassing is the natural process where the beans allow the excess CO2 to escape over time – all that’s required is to leave the beans to rest. The exact time required varies depending on a range of factors. The roasting level can have a significant impact (beans roasted to the point of pyrolysis and second crack have already vented a considerable amount of CO2, and in the process, the structure of the beans has been opened up to allow the remainder to escape more easily). But the brewing method and choices made during processing can also have an impact. As a rule though, degassing will generally take from 3 days to 3 weeks[11].

It should be noted that some carbon dioxide is necessary for brewing good coffee – coffee without CO2 is generally flat and stale. The key to degassing is to allow the optimum amount of CO2 to escape while retaining enough to contribute to the brewing process.

As the beans can sometimes lose freshness while degassing, it’s wise for professional roasters to package their beans before the degassing process completes. For this reason, many commercial brands of bagged coffee beans (normally packaged in plasticised foil to block out light) will also feature a CO2 valve on the packet, allowing the excess CO2 to escape without allowing oxygen back into the pack.

Coffee Shops vs home coffee roasters

Although Coffee roasting is now often regarded as a commercial process, the history of home coffee roasting is a lot older – the first known implements we have for coffee roasting date from Persia and the Ottoman empire around the 1400s. Even after the industrial revolution, commercial coffee roasting faced serious competition from home roasters. A.E. Forbes, writing in the 1850s reflected that “Selling roasted coffee was uphill work, as every one roasted coffee in the kitchen oven“[12]. Although the rise in popularity of instant coffee around the World War II period meant a drop in the prevalence of home roasting (creating space for coffee shops to establish themselves more as a prominent source of high-quality brewed coffee), there has always been a niche market in home roasting, which is still going strong today.

Home coffee roasting has particular advantages for coffee enthusiasts, allowing them to produce small batches of roasted coffee – roasting the beans, grinding them, and brewing them over a short time frame to ensure optimum freshness. It also allows those with a coffee roaster for home use to take advantage of high-quality single origin coffee and small batch coffee, tweaking their setup and roast profile to be optimised for the flavour profile of a specific type of bean. Thus home roasting has a particular appeal for third-wave coffee[13] enthusiasts.

Home roasting also has obvious financial benefits, as it allows the purchase of unroasted green beans at a lower cost than roasted beans from a commercial coffee roasting warehouse or local coffee shop. However, home coffee roasters also need to factor in the cost of any equipment purchased for coffee roasting. Coffee beans roasted in the oven or on the stovetop (both common methods of home coffee roasting) are very commercially efficient, but skill is needed for a good roast with such basic facilities – so there is a risk of losing money on failed batches. Coffee roasted in a hot air popcorn popper or even a dedicated coffee roasting machine for home use will require less skill, but the cost of this specialised equipment must now be factored into the overall cost.

Conclusion

The coffee roasting process is an extraordinarily complex one, with thousands of chemical processes[5] taking place while the beans heat up in the roaster. For most coffee drinkers, the choices are simple – do you prefer a light roast with more flavour and complex acidity or a hearty dark roast with smoky overtones (and slightly less caffeine)? Do you want something that will highlight the flavours of a particular brand of single origin coffee, or are you happy with a simple, unassuming blend that’s been well-roasted?

But regardless of the roast we choose or the type of beans we want, it’s worth appreciating the complexity of just what goes on inside the beans as they’re roasting – not to mention the amount of knowledge, expertise and skill that goes into producing well-roasted beans for a good, well-rounded cup of coffee.

References:

- Economics of Coffee – Coffee’s Statistics

- Physical changes coffee beans experience during roasting

- Coffee roasting basics: A guide to controlling charge temperature

- Maillard Reaction: The Key to Flavor Development

- The Coffee Roasting Process: What Roasting Actually Does To Coffee Beans

- What Is First Crack and How Do You Recognise It?

- Coffee Roasts – What are the Differences?

- Chemistry and Physics of Fire and Liquid Fuels

- Caffeine (National Center of Medicine)

- Methods for cooling roasted beans and their effects

- Coffee Degassing; What Does It Mean For Brewers & Roasters?

- All About coffee, by William H. Ukers, M.A. (1922)

- What Is “Third Wave Coffee”, & How Is It Different to Specialty?

About the Author:

Lochy Cupit

Author, Content Writer, Storyteller and Wordsmith

Lochy Cupit is a published author, professional content writer, content researcher, multimedia & web developer, youth worker, actor, radio presenter, podcaster, and creative arts specialist. He currently works as a content writer for a professional first aid training organisation. He holds bachelor’s degrees in computer science and multimedia, a masters in creative writing, and a graduate diploma in theology – because “why study just one thing”? He lives in Adelaide with his wife and two highly energetic boys.

Facts Checked By:

Dr. Richard Muhlack thoroughly reviewed this research and provided positive feedback on its quality. He carefully examined the research, and confirmed the accuracy of the information. Dr. Muhlack holds a PhD in Chemical Engineering and has acquired over twenty years of experience in the wine industry through various research and industry roles. His expertise spans across a diverse range of areas including process analysis and simulation, cleaner production, energy efficiency, renewable energy technology, waste treatment, and environmental management.